EXPERTISE

FROM A SINGLE SOURCE

A PASSION FOR METALWORKING

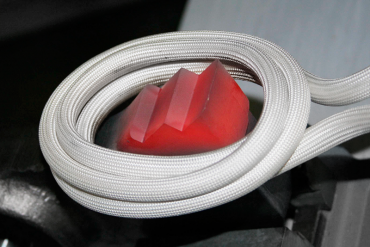

For more than 70 years, our passion has been metalworking. This enthusiasm drives us - it constantly spurs us on to innovations in products and processes.

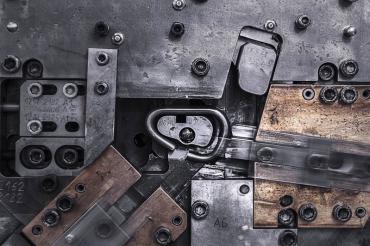

We are an ALL AT ONE PLACE partner for our customers. From product & process development to the forge and CNC machining to surface treatment, Schweiger offers the highest precision, process know-how and complete quality management. The high level of vertical manufacturing from raw materials to the finished and assembled component groups allows a very high degree of flexibility in the production planning of our customers.

PROCESS & PRODUCT DEVELOPMENT

INNOVATIVE PROCESSES FOR PRODUCTS OF THE HIGHEST QUALITY

In our material laboratory and the Schweiger workshops, products and processes are designed and developed for the highest customer requirements from prototyping production to ready for series production. Our specialists are regularly integrated in the development process of new products for customers at a very early stage.

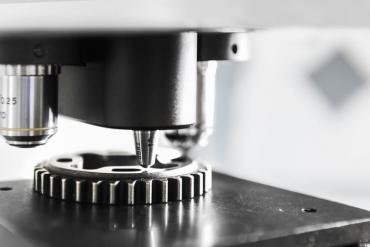

QUALITY MANAGEMENT

PRECISION AS STANDARD

Through early concentration of the product portfolio on safety-relevant components such as rope grips for ski lifts and cable cars, there is a high degree of quality awareness with decades of tradition at Schweiger. Since the beginning of modern quality management methods in the 1980s, the most accurate measurements, tests and complete documentation at Schweiger are a matter of course.